Multivibrators OverviewMultivibrators are essential electronic circuits that generate different types of waveforms, primarily square waves. They are categorized into three main types, each serving distinct functions in electronic applications:

1. Astable Multivibrator: This configuration continuously oscillates between its two unstable states, producing a square wave output without the need for external triggering. It is commonly used in applications such as clock pulse generation, LED flashers, and tone generation. 2. Monostable Multivibrator: This type has one stable state and produces a single output pulse when triggered. It is often utilized in applications like timers, pulse width modulation (PWM), and debounce circuits for switches.

3. Bistable Multivibrator: Also known as a flip-flop, this configuration has two stable states and can store binary information. It is widely used in digital circuits, memory storage, and data processing applications.

Core Functional Technology1. Transistor-Based Multivibrators: Traditional multivibrators are constructed using bipolar junction transistors (BJTs) or field-effect transistors (FETs). The feedback mechanism between the transistors determines the circuit's state, allowing for oscillation or pulse generation.

2. Integrated Circuit (IC) Multivibrators: Modern multivibrators are often implemented as integrated circuits, such as the popular 555 timer IC. This IC can be configured for both astable and monostable operation, simplifying design and reducing the number of discrete components required.

3. Digital Multivibrators: In digital electronics, multivibrators can be created using logic gates (e.g., NAND or NOR gates) to form flip-flops and other sequential circuits. These digital implementations are crucial for modern computing and data storage.

Application Development Cases1. Timing Applications: Multivibrators are extensively used in timing circuits. For instance, the 555 timer IC in monostable mode can generate precise time delays for applications such as LED blinking, where the timing of the on/off cycle is critical.

2. Frequency Generators: Astable multivibrators are employed to produce clock signals for microcontrollers and digital circuits. They are vital in applications requiring regular timing signals, such as in communication systems and frequency modulation.

3. Pulse Width Modulation (PWM): Monostable multivibrators can generate PWM signals, which are essential for controlling the speed of motors or the brightness of LEDs. This technique is widely used in power management applications, such as in electric vehicles and lighting systems.

4. Data Storage: Bistable multivibrators (flip-flops) are fundamental components in digital memory systems. They are used in registers, counters, and memory cells to store binary data, playing a crucial role in computer architecture and digital signal processing.

5. Signal Conditioning: Multivibrators can be utilized to clean up noisy signals by converting them into clean square waves. This application is particularly useful in sensor systems, where accurate signal representation is necessary for reliable data interpretation.

ConclusionMultivibrators are versatile components in both analog and digital electronics, with applications ranging from simple timing circuits to complex data storage systems. Their ability to generate and manipulate waveforms makes them essential in a wide array of electronic devices. Understanding their core technologies and applications can lead to innovative designs and solutions across various fields of engineering, enhancing the functionality and efficiency of electronic systems.

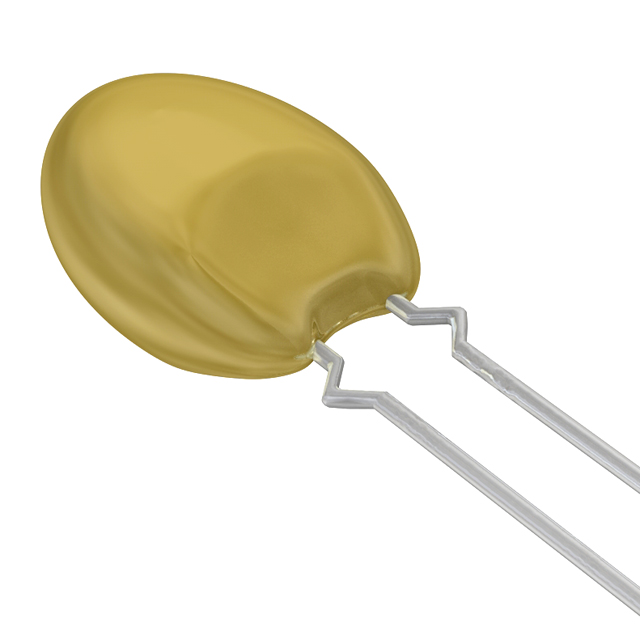

Application Development in Drivers, Receivers, and Transceivers for 1N5238B-T: Key Technologies and Success StoriesThe 1N5238B-T is a widely used Zener diode that serves critical functions in voltage regulation and protection across various electronic applications. Its integration into drivers, receivers, and transceivers showcases its versatility and effectiveness in enhancing electronic system performance. Below, we explore the key technologies associated with the 1N5238B-T and highlight notable success stories across different industries.

Key Technologies1. Voltage Regulation2. Signal Clamping3. Transient Voltage Suppression (TVS)4. Biasing and Reference Circuits5. Low-Noise Applications1. Telecommunications2. Consumer Electronics3. Automotive Applications4. Industrial Automation5. Medical Devices Success Stories ConclusionThe 1N5238B-T Zener diode is a vital component in the development of drivers, receivers, and transceivers across multiple industries. Its key technologies, including voltage regulation, signal clamping, and transient voltage suppression, significantly contribute to the reliability and performance of electronic systems. The success stories in telecommunications, consumer electronics, automotive applications, industrial automation, and medical devices underscore its versatility and importance in modern electronic design. As technology continues to evolve, the role of the 1N5238B-T in enhancing electronic performance will remain critical.

Certainly! Here’s a more detailed exploration of encoders, decoders, and converters, focusing on their core functional technologies and application development cases.

Encoders1. Rotary Encoders: Measure the angular position of a rotating shaft. They can be incremental (providing relative position) or absolute (providing a unique position value).2. Linear Encoders: Measure linear displacement, often using optical or magnetic methods to provide high precision.3. Digital Encoders: Convert data into a specific coded format, such as binary, Gray code, or other encoding schemes.1. Binary Decoders: Convert binary input signals into a single active output line.2. BCD Decoders: Convert Binary-Coded Decimal inputs into decimal outputs, often used in display applications.3. Address Decoders: Select specific memory locations in microcontrollers or memory chips based on input addresses.1. Analog-to-Digital Converters (ADC): Convert continuous analog signals into discrete digital data, enabling processing by digital systems.2. Digital-to-Analog Converters (DAC): Convert digital data back into analog signals for output to devices like speakers or displays.3. Level Shifters: Adjust signal voltage levels to ensure compatibility between components operating at different voltage levels.Robotics: In robotic arms, rotary encoders provide feedback on joint angles, enabling precise control and movement. For example, a robotic arm in a manufacturing line uses encoders to ensure accurate positioning for assembly tasks.Robotics: In robotic arms, rotary encoders provide feedback on joint angles, enabling precise control and movement. For example, a robotic arm in a manufacturing line uses encoders to ensure accurate positioning for assembly tasks.CNC Machines: Linear encoders are critical in CNC (Computer Numerical Control) machines, where they track the position of the cutting tool, ensuring high precision in machining operations.CNC Machines: Linear encoders are critical in CNC (Computer Numerical Control) machines, where they track the position of the cutting tool, ensuring high precision in machining operations.Consumer Electronics: Digital encoders are used in devices like remote controls, where they convert button presses into digital signals that can be processed by microcontrollers.Consumer Electronics: Digital encoders are used in devices like remote controls, where they convert button presses into digital signals that can be processed by microcontrollers.Microcontroller Systems: Address decoders are used in microcontrollers to access specific memory locations, allowing for efficient data management and retrieval in embedded systems.Microcontroller Systems: Address decoders are used in microcontrollers to access specific memory locations, allowing for efficient data management and retrieval in embedded systems.Digital Displays: BCD decoders are utilized in digital clocks and calculators to convert binary inputs into human-readable decimal outputs, enhancing user interaction.Digital Displays: BCD decoders are utilized in digital clocks and calculators to convert binary inputs into human-readable decimal outputs, enhancing user interaction.Data Communication: Binary decoders are employed in communication systems to decode received signals, ensuring accurate data interpretation and processing.Data Communication: Binary decoders are employed in communication systems to decode received signals, ensuring accurate data interpretation and processing.Audio Systems: DACs are crucial in audio playback devices, converting digital audio files into analog signals that can be amplified and played through speakers, enhancing sound quality.Audio Systems: DACs are crucial in audio playback devices, converting digital audio files into analog signals that can be amplified and played through speakers, enhancing sound quality.Sensor Applications: ADCs are widely used in sensor systems, such as temperature sensors, where they convert analog voltage signals into digital data for processing by microcontrollers, enabling real-time monitoring and control.Sensor Applications: ADCs are widely used in sensor systems, such as temperature sensors, where they convert analog voltage signals into digital data for processing by microcontrollers, enabling real-time monitoring and control.IoT Devices: Level shifters are essential in IoT applications, allowing communication between components that operate at different voltage levels, ensuring reliable data transmission in smart devices.IoT Devices: Level shifters are essential in IoT applications, allowing communication between components that operate at different voltage levels, ensuring reliable data transmission in smart devices. Decoders Converters ConclusionEncoders, decoders, and converters are fundamental components in modern electronic systems, enabling the effective processing, transmission, and interpretation of data across various applications. Their integration enhances functionality, accuracy, and efficiency, making them indispensable in fields such as industrial automation, consumer electronics, and the Internet of Things (IoT). As technology advances, the development of more sophisticated and efficient encoders, decoders, and converters will continue to drive innovation and improve system performance across diverse applications.